Techflow Enterprises Pvt Ltd is one of the primary and most trusted providers of outcome products like Air pollution control devices, Dust collection system for sand plant, Pulse Jet Cartridge Filter, Dust Recovery systems, Dust Collector, Fabric Filter, Silo Vent filters, Online cleaning bag filter, Off line cleaning bag filter, bag filter, De-dusting system, Bag house, Flue gas emission control system, Cassette type filter, Reverse air cleaned bag filter, Centrifugal fans and blowers, Furnace fume extraction system, Welding fume extraction system, Pneumatic conveying system, Pulse jet bag filter, and Electro static precipitator (ESP) in India with worldwide exports.

Techflow has been one of the enormous manufacturers of Dust collection systems for sand plant since 1980.

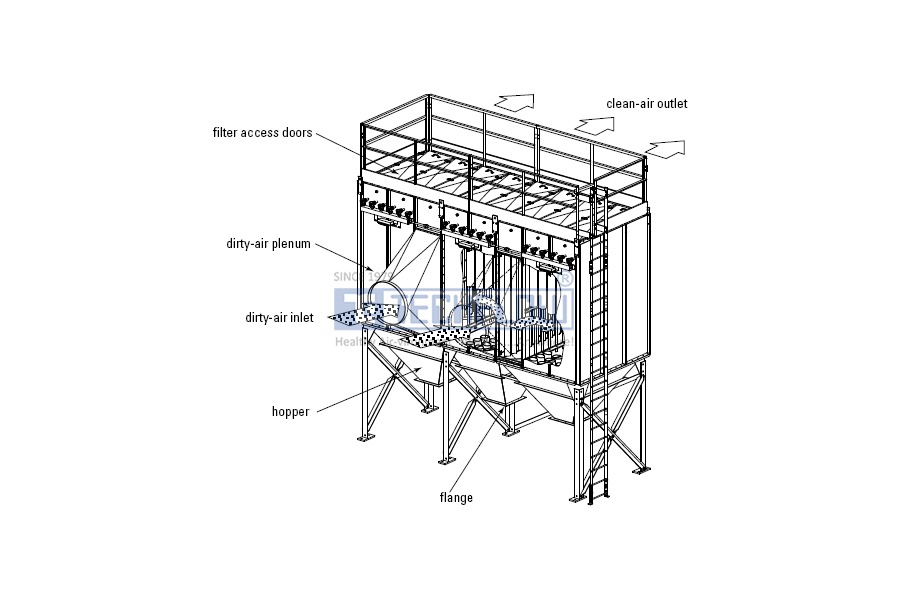

This de-dusting system is an exceptional form of horizontally mounted filter bag envelopes (pockets) up on retaining metal cages. The privilege is lower height & filter bags are easy to access for maintenance & substitute.

These de-dusting systems are suggested where there is a height limitation or front loading of filter components is mandated.

Cleansing of bags is achieved through reverse consolidated air timed pulses.

Discover more| Dust collection system for sand plant |

|---|

|

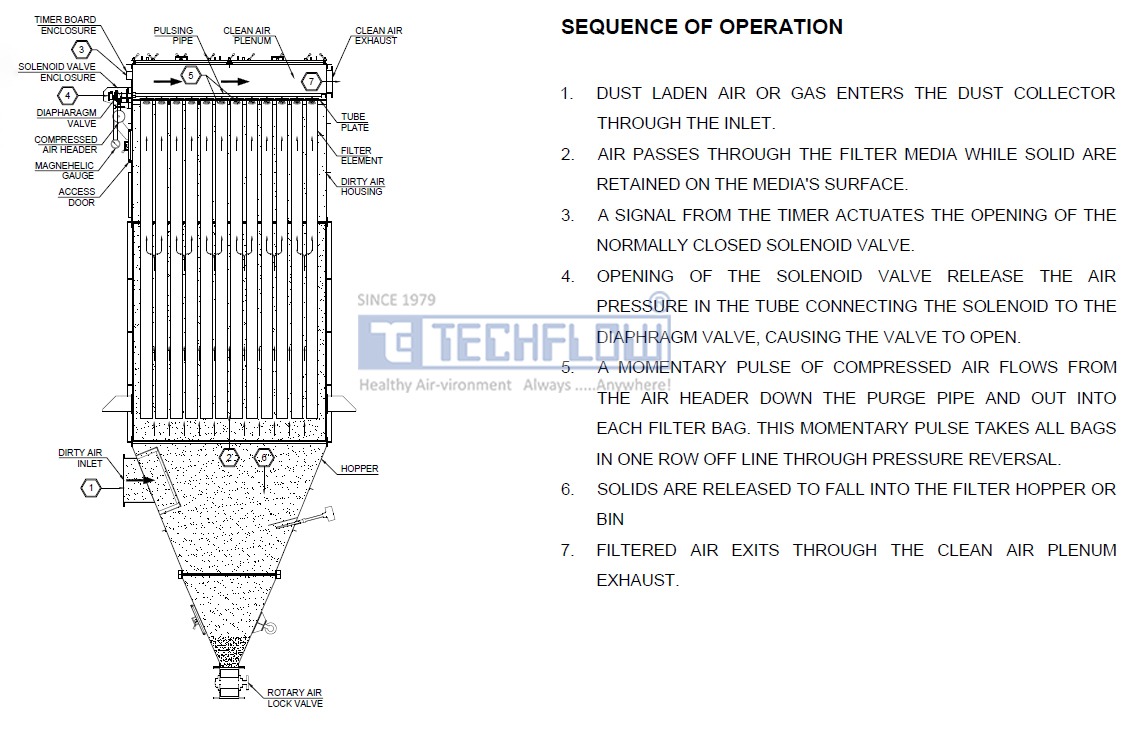

1. OPERATING PRINCIPAL (ONLINE CLEANED)

Dust stuffed air enters the collection hopper where heavier particles slip out of the air stream. The lighter particles are entrapped in the air stream and climb into the filter bags. As the air passes through the filter bags, the dust particles are collected on the outermost surface of the filter bags, and the cleansed air is depleted through the collector. At even intervals, jet sprays of compressed high-pressure air pass through the venturis via the blow pipes and pulse valve, causing a strong flow of secondary air, briefly reversing the airflow through the bags. This produces an interior shock wave that crosses down the length of the bag, forcing the bag to push and stretch outwards. This permits reversed airflow to displace cumulative dust on the outward of the bag where it falls into a collection hopper. With this approach to cleaning, airflow through a row of bags is switched for only a piece of a second, resulting in steady-state airflow situations across the dust collector. The cleansing operation is controlled by a smoothly adjusted solid-state timer. A Differential Pressure meter enables optimum regulation of the timer. Pulse durations and pulse gaps can be absolutely and accurately set at the timer to minimize compressed air ingestion.

2. General Function of Dust collection system for sand plant

For cleansed releasing of flue gas transmissions from removing fine particles & control of SPM level Unit has been created & manufactured as per mutual prior discussions & technical understanding on variables like Air to cloth ratio, Dust loading, Existing & new bag cage sizes Can velocity, Inlets/ outlets, Heaters, Control system, etc.